Zhejiang Qingyou Material Science and Technology Co., Ltd.

Qingyou Materials is a high-tech enterprise engaged in research and development, production, and sales. The company focuses on the field of new energy vehicle materials, providing thermal management solutions at the cell level, module level, PACK level, and vehicle level. Qingyou's series of products have been supplied to various vehicle and PACK enterprises, including BYD, SAIC, Chery, EVE Battery, Lishen, MGL, National Power, Weihong Power System, SVOLT Energy, FUNENG, Gotion High-tech, and others.

Sustainable development goals

Policy Background:The electrification of automobiles is crucial for the decarbonization of the transportation sector, with the growth of new energy vehicles leading to a surge in demand for power batteries. Driven by both policy and market forces, the carbon emissions throughout the entire lifecycle of power batteries (carbon footprint) are becoming a focal point for governmental and corporate attention. Initiatives such as the European Union's "New Battery Regulation" mandate that, starting from July of this year, automotive batteries exported to the EU must declare their product carbon footprint, and from 2026 onwards, they must hold a "Battery Passport" to be sold in the EU market as part of the focus on green trade.

Industry Chain Background: The development of new energy vehicles aims to reduce carbon emissions, and as the "heart" of these vehicles, power batteries contribute to about half of the total carbon emissions throughout the vehicle's lifecycle. Against the backdrop of intensifying global climate change, automotive OEMs and battery pack enterprises are embarking on green upgrades and transformations to meet the low-carbon development demands of both policies and markets. They are gradually strengthening the management of product carbon footprints and supply chain carbon emissions. However, whether conducting carbon footprint accounting for battery products or managing supply chain carbon emissions, precise collection of carbon data from upstream suppliers in the industry chain is necessary. Consequently, automotive or battery enterprises seek accurate, credible, and traceable carbon emission data from upstream companies.

Business pain points

Qingyou Materials has been requested by downstream chain-leading enterprises such as BYD to "provide carbon footprint data for the supplied products".

Qingyou Materials recognizes that product carbon footprint data is gradually becoming the "green passport" for product sales, and that these data must be calculated and traceable based on scientific methods. Qingyou Materials Materials has found that achieving carbon footprint certification solely through its own efforts is extremely challenging:

Carbon footprint accounting - Data challenges. The process of carbon footprint accounting not only involves the company's own production data but also requires the collection of upstream material-related carbon data, consuming time and effort to obtain crucial data. Additionally, there is currently no universally applicable activity factor database for the battery industry, and some activity factors still need to be obtained through literature research and other means.

Carbon footprint accounting - Modeling challenges. Accurately calculating the carbon footprint of the entire product lifecycle requires precise modeling. In the absence of professional carbon accounting talent, the accounting results are likely to be questioned by downstream enterprises.

Carbon footprint certification - Authority needed. After completing the carbon footprint accounting for products, obtaining a carbon footprint certificate ensures the authority of the carbon footprint data. This can be seen as obtaining a stamp for the product's "green passport."

Carbon data system - Traceability challenges. The traditional method of collecting and calculating data using spreadsheets is no longer sufficient to meet the increasingly stringent carbon data traceability requirements of downstream enterprises. Companies need a digital carbon management system to ensure data security while meeting the verification and traceability needs of downstream enterprises and government agencies for carbon data of products/companies.

Integrated solution

Through the product carbon footprint accounting and certification services provided by CarbonNewture, and by utilizing the CarbonNewture digital carbon management platform, Qingyou Materials has completed the carbon footprint accounting and certification for three core products. The carbon data has been transmitted to downstream customer BYD as required.

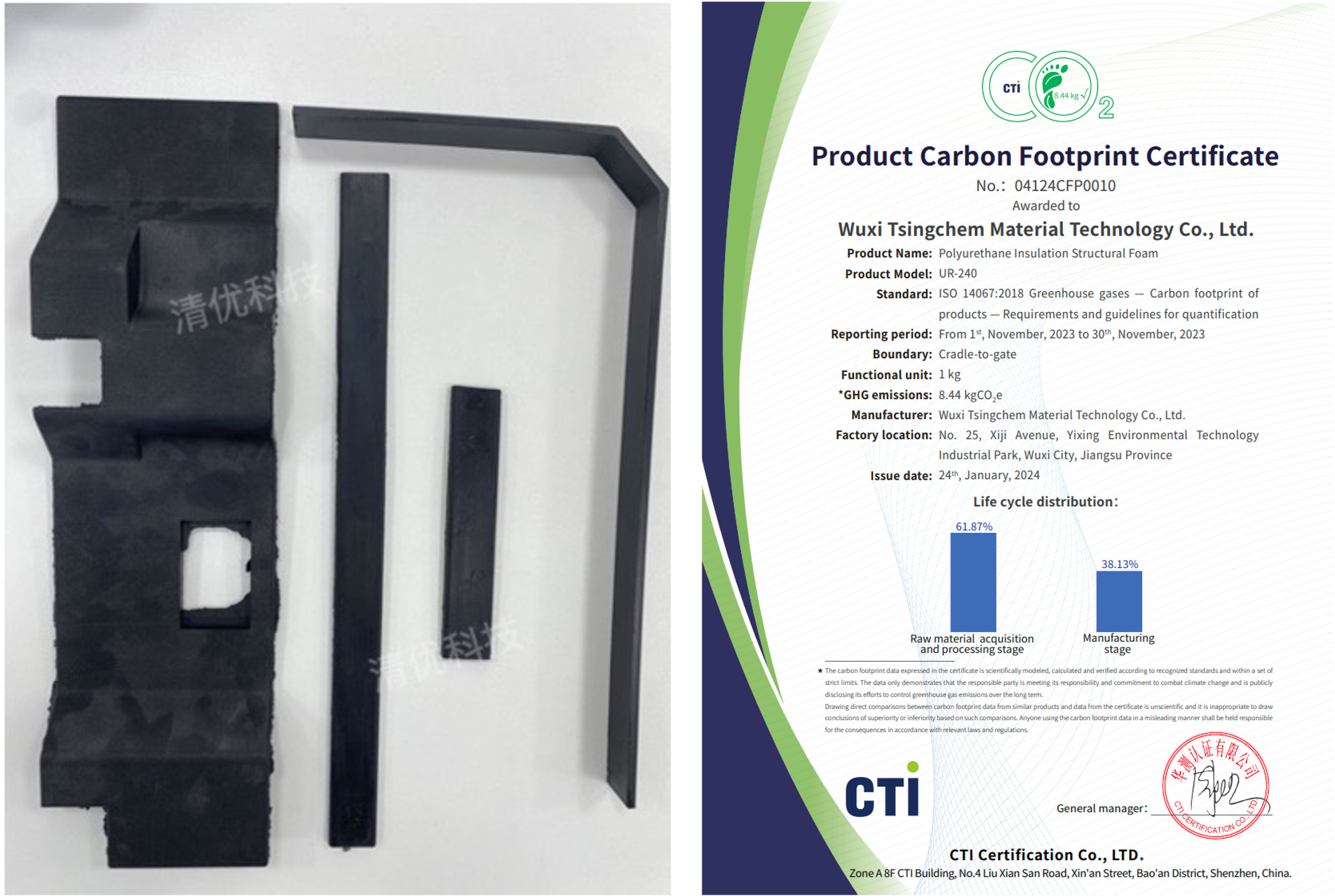

The Carbon Footprint Certification Certificate of Qingyou Materials

Carbon footprint calculation and certification - product series 1

Qingyou Materials produces coated soft foam cushioning materials UF-440 and UF-471, which are PU cushioning foams. When used between battery cells, they can absorb the expansion stress of the cells, contributing to the improvement of the cycle life of power batteries. In non-cell applications, these materials can be used for module support beneath, collision prevention and insulation above the module, and prevention of adhesive leakage at the edges of water-cooled plates, among other purposes.

Carbon footprint calculation and certification - product series 2

Qingyou Materials produces polyurethane insulation structural components UR-240, which are designed for the insulation structure of new energy power batteries and energy storage battery systems. These components help maintain a stable operating temperature during system operation, reducing the energy consumption of power battery packs. Additionally, they help delay the loss of charge in batteries when exposed to high or low-temperature environments, thus optimizing overall performance.

UR-240 polyurethane thermal insulation structural parts product and its carbon footprint certificate

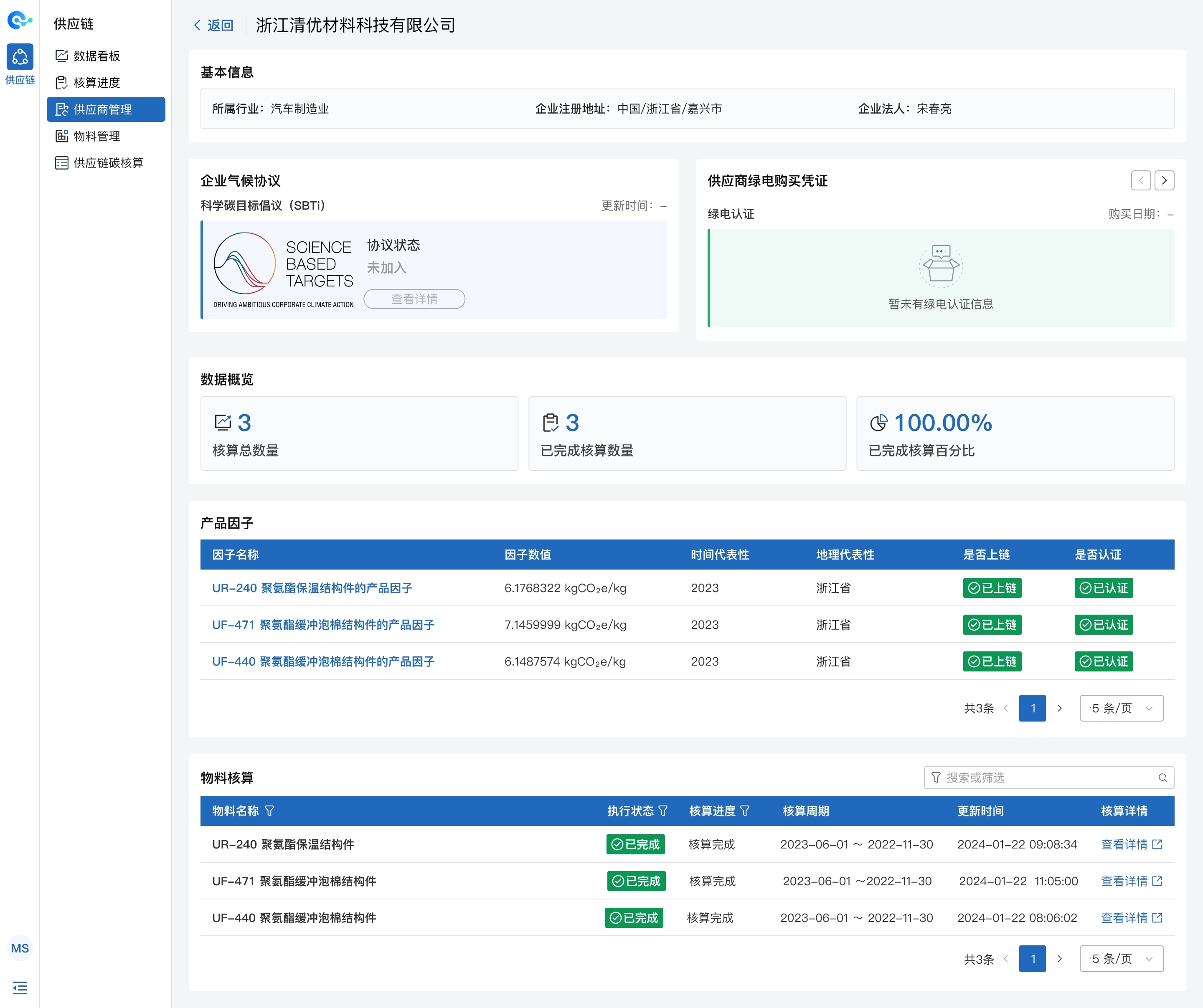

Chain master enterprises require a more intelligent supply chain carbon emission management platform

To manage the carbon footprint and scope three carbon emissions of automobiles, it is necessary to collect a vast amount of carbon data from upstream enterprises. A single automotive company typically has hundreds or even thousands of primary suppliers, not to mention secondary suppliers and distant raw material suppliers, making it challenging to manage such a diverse and extensive network through traditional methods.

Utilizing digital technologies such as blockchain, big data, and IoT, CarbonNewture has developed a Supply Chain Carbon Emission Management Platform. This platform allows for the quantification of carbon emissions at the production level while efficiently managing multiple levels of upstream supply chain enterprises. Moreover, the confidentiality, privacy, and security of data are also ensured.

Chain-leading enterprises like BYD can not only use real-time dashboards to monitor the submission status of carbon footprint data from upstream supply chain enterprises but also confirm supply chain emission reduction progress based on real-time data. This enables them to advance supply chain emission reduction goals by optimizing procurement strategies.

CarbonNewture Supply Chain Emission Management Platform- Dashboard

CarbonNewture Supply Chain Emission Management Platform-Supplier management interface

By utilizing CarbonNewture's Supply Chain Carbon Management Platform, we refine the granularity of carbon data, monitor and manage carbon reduction in the supply chain in real-time, scientifically break down carbon reduction goals, and truly drive enterprises to achieve comprehensive carbon neutrality.