Recently, with support from Carbon Newture, Zibo Luhua Hongjin New Material Group Co., Ltd. (hereinafter referred to as "LUHUA Hongjin") completed the carbon footprint calculation for 16 core products across its Zibo, Tianjin, and Wuhan facilities. Carbon Newture has provided LUHUA Hongjin with carbon footprint management services for two consecutive years to meet its internal carbon management requirements and those of its downstream customers for supply chain carbon management.

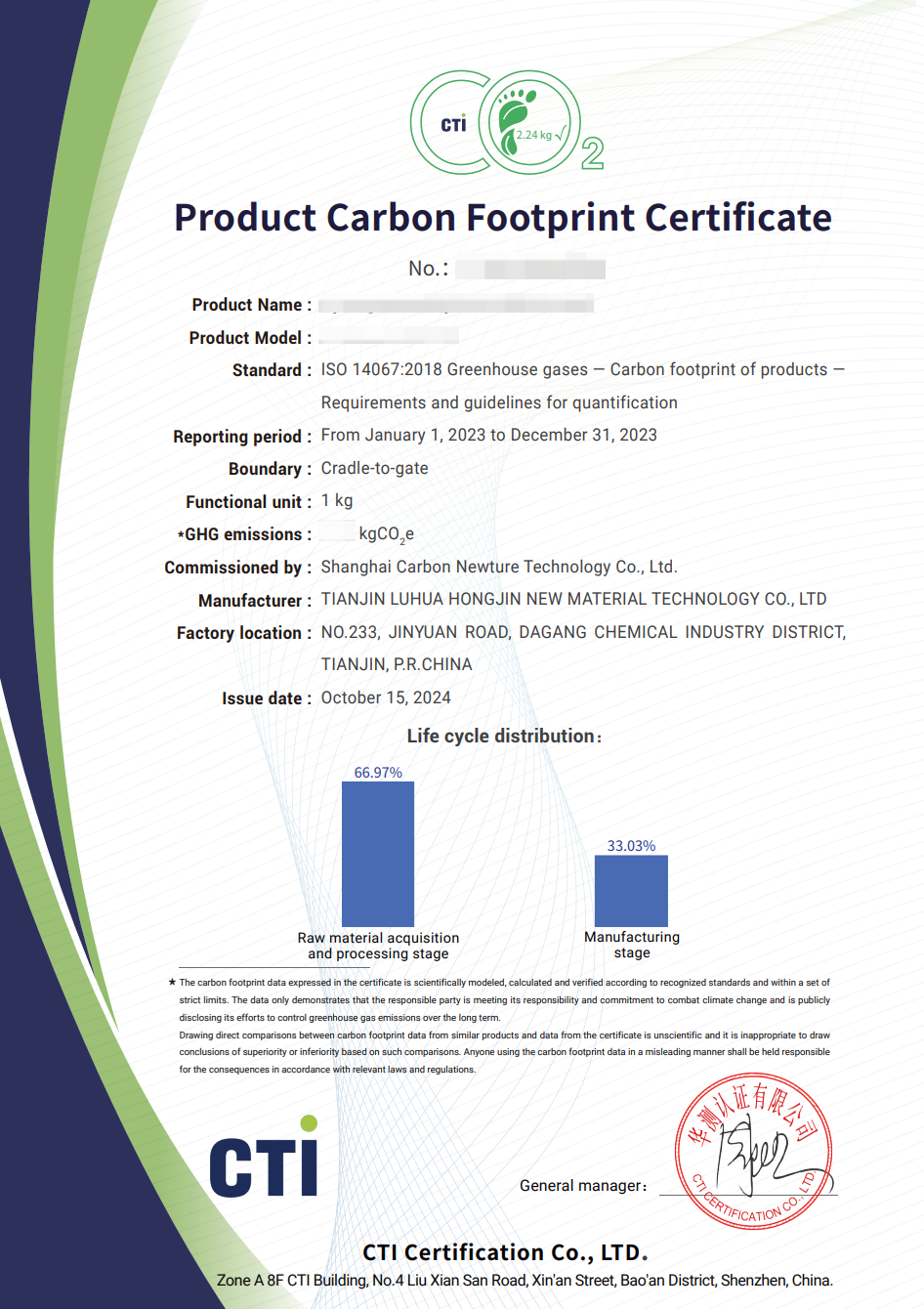

Product Carbon Footprint certificate of LUHUA Hongjin

01 Supply Chain Carbon Management:

A necessary path for emissions reduction in the chemical industry

In recent years, production capacity in the chemical industry has continued to expand significantly, with a nearly 15% increase in the production capacity of 24 major chemical products domestically in 2023[1]. This has intensified market competition in the chemical sector. As a critical pillar of China's national economy, the chemical industry is also one of the primary sources of greenhouse gas emissions within the industrial sector. As carbon neutrality goals gain global consensus, the transition from goal-setting to execution has accelerated[2], advancing climate action efforts globally in a more in-depth and comprehensive direction. Chemical companies domestically and abroad, such as Henkel, Dow, and BASF, are increasingly raising carbon management requirements for suppliers. For example, they require suppliers to complete a sustainable procurement audit (TfS), in which product carbon footprint is a mandatory item.

Why do leading chemical companies place such emphasis on supply chain carbon management?

Taking Henkel as an example, according to its 2023 Sustainability Report[3], Scope 3 emissions account for 99% of its value chain’s total emissions, with carbon emissions from upstream raw materials making up nearly one-quarter of this total. Consequently, Henkel has set a target to reduce CO₂ emissions per ton of raw materials and packaging by 30% by 2030 compared to 2017, holding its suppliers accountable to this goal.

Image source: Henkel Sustainability Report 2023

Despite the complexity of the chemical supply chain, the vast variety of products, and the extensive network of suppliers, the product remains the core unit within the value and supply chains. Therefore, tracking product carbon footprint data along the supply chain and improving the transparency and accuracy of carbon data are essential to driving emissions reductions across the value chain.

02 LUHUA Hongjin joins chemical industry partners to build a green, low-carbon supply chain

LUHUA Hongjin is a high-tech enterprise specializing in the research, development, production, and sales of polymer-based new materials. It is dedicated to the comprehensive processing and utilization of carbon-5 and carbon-9, by-products of cracked ethylene, making it one of the leading companies in carbon-5 and carbon-9 resource utilization in China. LUHUA Hongjin is also a leading domestic producer of tertiary amine products related to the carbon-4 industry and a top-tier raw material supplier in the adhesives field. With its strong competitive advantage, LUHUA Hongjin has established long-term, stable partnerships with key upstream suppliers such as Qilu Petrochemical, Maoming Petrochemical, and Wuhan Petrochemical under Sinopec, as well as with high-quality downstream clients like Henkel, Michelin, H.B. Fuller, Bostik, Giti Tire, and Zhongce Rubber.

Image source: Zibo Luhua Hongjin New Material Group Co., Ltd.

LUHUA Hongjin has long been committed to building an “environmentally friendly enterprise” and achieving sustainable economic, environmental, and social development through energy-saving and efficiency-enhancing measures, such as technological upgrades and energy management. As a company managing carbon emission allowances, LUHUA Hongjin actively cooperates with carbon verification efforts and fulfills its obligations on time. As a midstream chemical company, LUHUA Hongjin aids in supply chain emissions reduction by calculating product carbon footprints, connecting carbon data across the upstream and downstream supply chain, and enhancing carbon data transparency within the industry.

As shown in the image below, LUHUA Hongjin also uploads its product carbon footprint data to the China Carbon Disclosure Platform for Machinery and Electronics transparent reporting, allowing stakeholders to fully understand and trust the compliance of its carbon data. The platform leverages digital technologies like blockchain to enhance carbon management, ensuring data integrity, security, privacy, transparency, traceability, and an unalterable record.

Disclosure page of the product

Using our self-developed digital carbon management platform, we at Carbon Newture have provided LUHUA Hongjin with carbon footprint management services for two consecutive years to meet both LUHUA's own carbon management needs and those of its downstream supply chain clients.Data indicates that LUHUA Hongjin has achieved significant progress in emissions reduction in recent years; for instance, the carbon intensity of core carbon-5 product A and carbon-9 product B at the Wuhan facility decreased by 7% and 11%, respectively, in 2023 compared to 2022, while the carbon intensity of SIS elastomer product C at the Zibo facility decreased by 11% over the same period.

By continually calculating product carbon footprints and implementing emissions reduction measures, LUHUA Hongjin demonstrates its commitment to addressing climate change. Looking ahead, LUHUA Hongjin will continue to advance in green and low-carbon development, ensuring the reliability and compliance of its carbon data, reducing its own emissions, and working with upstream and downstream supply chain partners to build a green, low-carbon supply chain.

References:

[1]http://www.sinopecnews.com.cn/xnews/content/2024-05/22/content_7095915.html

[2]《全球碳中和年度进展报告》,清华大学碳中和研究院

[3]Henkel Sustainability Report 2023: https://www.henkel.com/resource/blob/1935232/ae7bc192da78ab3ea1be5c12f764d63d/data/2023-sustainability-report.pdf